“For a clean future”

Our products for exhaust air and gas purification are highly efficient and individually adaptable, keeping them in compliance with the highest environmental standards and minimizing energy consumption.

We decided to develop, design and manufacture the key technology of dryer heating and exhaust air purification by means of a thermal afterburning system in-house (Ahaus site). The objective was to create a highly efficient heating system which undercuts current exhaust gas limits.

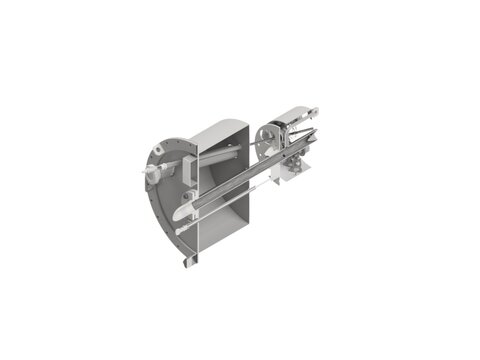

The new WENKER PREMIX is a directly ignited, secondary air burner for heating process gas. It uses the oxygen in the process gas for combustion and therefore does not require any additional combustion air. As a result, the burner consumes very little energy.

Design features

Regenerative thermal oxidation of pollutants is another similarly efficient method of thermal exhaust air purification.

Wenker RTOs (regenerative thermal oxidizers) consist of three process chambers, to which further modules can be added.

Raw gas supply and clean gas discharge are controlled by pneumatically actuated disc valves.

Wenker RTOs: innovative, efficient and economical.