Production technology is in the midst of a huge transition. At a time when expectations of efficiency, quality and sustainability are rising in global markets, we are also seeing increasingly strict requirements and regulations. The time has come for entirely new solutions. And that’s were we come into play. At Wenker, we help our clients meet the challenges that come with sweeping change. With comprehensive, systematic solutions.

Our innovations in the field of application and separation technology round out our solutions for your paint processes. Maximum performance, extreme convenience and results that set new standards of quality.

Perfection in the flow of production

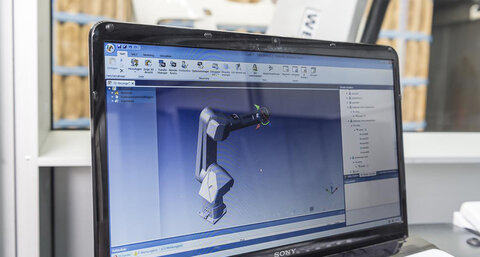

Robots are essential to ensure that the paint is applied only to the desired areas and in the desired quantity. They reduce the amount of overspray and work without fatigue. Preferably, manipulators with hollow-wrist wrists are used, with no free-moving hoses above or next to the workpieces, to avoid surface contamination.

Another option: a component scanner in the infeed area records the shape of the workpiece as it is conveyed into the booth. The process data is processed and your workpiece is painted in real time. In addition, the convenient software allows offline programming and thus the creation of painting programs during the process. There are no pauses and no loss of time.

Automated painting processes guarantee precision and speed, but every component is different. Here, too, we can respond. We offer you, different atomizers adapted to your needs. The design of Wenker paint booths also allows robot assembly for different positions.

Work processes always require a flexible supply of materials. And flexibility defines us here as well. We can provide as many different paints as you need in tiny batches or large volumes. We offer a modular format for all standard container sizes, which reduces costs. For custom orders, we will design and manufacture containers in the dimensions you need.

Our containers are equipped with pneumatic or electric agitators. A speed monitor keeps the stirring process constant, while a minimum level sensor, an ultrasonic sensor or radar can also measure the filling quantity at the same time. A pneumatic lid lifter makes raising the lid precise and easy.

Application systems have a critical influence on the investment and operating costs of a paint system. Material usage, precision and efficiency are the most important indicators that the paint process is economical and working perfectly.

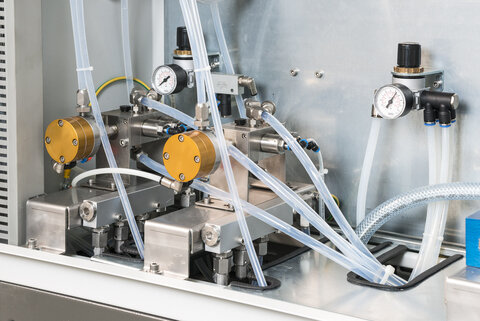

As a coating specialist, you work with a wide variety of materials in your production process. The Wenker mixing and dispensing system allows you to apply as many components as you need in one step, in exactly the right amount.

We can configure our mixing and dispensing system for water-based or solvent-based paints, depending on your needs. You can choose the number of paints you want, as well as the number of curing and rinsing agents you need. Precisely applied and dispensed, all in one operation.

Gear or screw pumps are used for dispensing and ensure precise, consistent application. The electronic control with its individually editable washing programs maximizes efficiency, enables fast paint changes and reduces costs. Technology that is safe and easy to operate guarantees process reliability.

A particular advantage of our robot-based painting processes is the scanner. It can detect any shape and size, even in motion. . It detects the shape in the infeed area of the workpiece as it is conveyed into the booth. Depending on the size and complexity of the parts, scanner equipment can be equipped with a different number of scanner heads to optimally capture the dimensions of your workpiece.

For the acquisition and processing of the parameters, powerful software is available. The process data of the workpiece is processed by the software - here a test run is simulated to avoid collisions and then sent to the painting robot. Thus your workpiece is processed in real time.

Due to our many years of experience and know-how in plant engineering, we can react flexibly and quickly to your different requirements for the workpieces. We plan, manufacture and assemble your scanning devices in-house and from one source.

On your request, we accompany the control-technical connection and project the entire work process.