Bodies-in-white and components need protection right from the start, with pretreatment and initial dip coating providing the foundation for subsequent coatings. The pretreatment process involves cleaning and degreasing the parts/components. This is followed by the e-coat process, where components receive their first coat to prevent corrosion. As the demands on the resistance of coatings are constantly increasing, we work to continuously optimize and develop our products.

To clean and pretreat plastic parts, we generally use power wash facilities, which clean and degrease the components to be coated.

We also offer the following methods as alternatives.

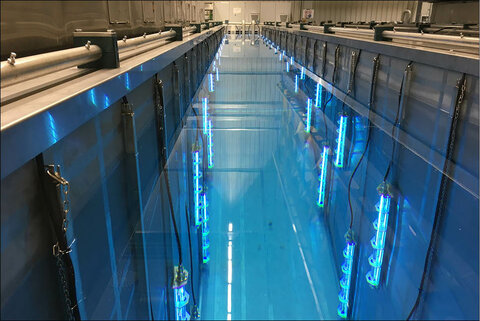

Wenker also plans, designs and implements turnkey galvanizing systems. Because galvanizing technology requirements have risen continuously in recent years, you need a reliable partner with the right expertise.

Wenker can offer you start-to-finish solutions.