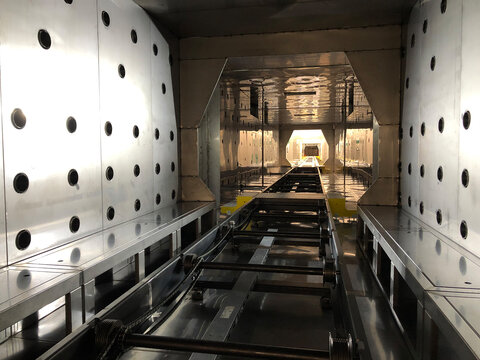

The coating or painting process is only as perfect and as economical as the subsequent drying process! For this reason, we stand for the development and production of high-quality dryers, dryer assemblies and modules. The implementation of future-oriented drying processes with new dryer control systems and innovative developments in process and control technology are just as much part of our scope of supply as heating units, exhaust air purification systems and the necessary accessories. Our dryers are among the most energy-efficient in the world! We use a circulating air system with as little exhaust air as possible and set standards in the automotive and automotive supplier sector with dryer temperatures of up to 220 °C (KTL dryer). Our own assembly specialists also ensure the optimal installation of the units on site, as well as the tightness of the dryer in case of a welded design.

The DRY-E-FFICIENT® oven scores with up to three times lower heat losses, due to its highly efficient, patented housing.

The complete E-heating enables a more Co²-neutral operation than conventional automotive dryers, in terms of environmental protection.

Our uniquely compact design, in addition to the integrated heating technology in the side walls and the stable frame construction, allows additional use of the dryer ceiling as an optimal production area - or car- storage.

The electric oven was designed according to the modular concept:

An Advantage of this design is the variable setting of the process temperature and air volume per cycle, as well as a product change, which has been optimized for the variable heating behavior of e-carbodies.

In addition, our developed "Plugin and Run" system shortens the installation and commissioning time at the customer's site.

Through targeted Co² savings, as well as reduction of heat emissions, we ensure our customers compliance with environmental standards and optimization of their production lines.

We are setting new standards in energy efficiency with smart ovens for the automotive sector.

The Oven emits 70% less transmission heat to the outside than conventional automotive dryers with a special construction without thermal breaks.

It can be individually adapted to customer-specific requirements thanks to its overall modular design.

This proceeding enables a shortened implementation speed up to the start of production.

We ensure compliance with the highest environmental standards and lowest energy consumption for our customers.

Energy-efficient Oven Units Using State-of-the-Art Technology

We developed our HOT.EFFICIENT units so they would not form thermal bridges to the outer hall and were able to reduce transmission heat loss by up to 70%.

Thermodynamic control (TDC) of our thermal incinerators allows us to adjust the performance of variable volume flows in our oven systems.

To cover the entire range of performance requirements, we have increased the control range between the minimum and maximum air volumes.

Particular advantage of our thermodynamic control is the cost savings in the drying process of car bodies.

With the demand-based exhaust air volume control , dryers can be optimally adapted to the production workload.

About the function:

When the dryer load is low, either due to smaller car bodies or also due to lower production quantities, the exhaust air volume is automatically controlled.

The aim of our "demand-based exhaust air volume control" is to automatically balance the dryer air volume with variable exhaust air volumes and matching (supplied) fresh air volumes.

With our new BAR system, energy savings of up to a maximum of 45% at partial load are achievable. In addition, the average energy saving due to fluctuating operation is 25%.